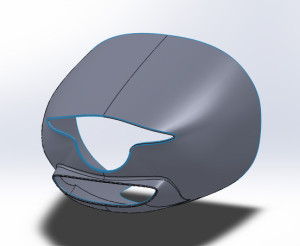

After the cowl design is finalized and 3D CAM model is ready it is time to create the core model of the cowl. In order to reduce the costs we are doing the positive mold here, so the fiberglass shells will be created directly on the core model.

When the part is ready it is trimmed, sanded and finally removed from the core.

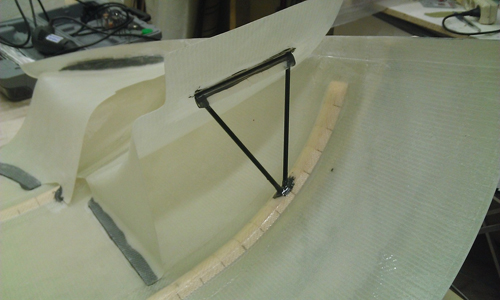

Along this there are shells for intake cooling channels that are fabricated separately from main shells. When ready the cooling channel shells are installed into main shells using structural epoxy adhesive.

Intake channels are additionally fixed by 6mm pultruded carbon fiber tubes in order to increase stiffness and reduce vibrations.