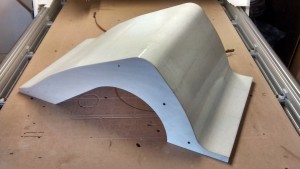

After multiple revisions of seat design we came up to a rather simple solution. The seat itself would be a glass fiber sandwich shell made on a 2-D extruded mold. Such a simple technology would produce a strong and lightweight seat. See the mold-making process below:

A piece of styrofoam was put between two CNC-milled end-profiles. The excessive foam was removed along the profiles with a hot wire. The styrofoam surface was then finished with a two layers of glass fiber. This surface will be re-finished and ready to make the seat shell.

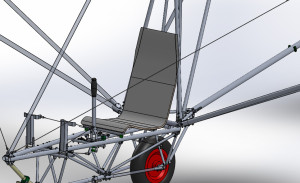

And this is how the seat assembly will fit in the cabin: